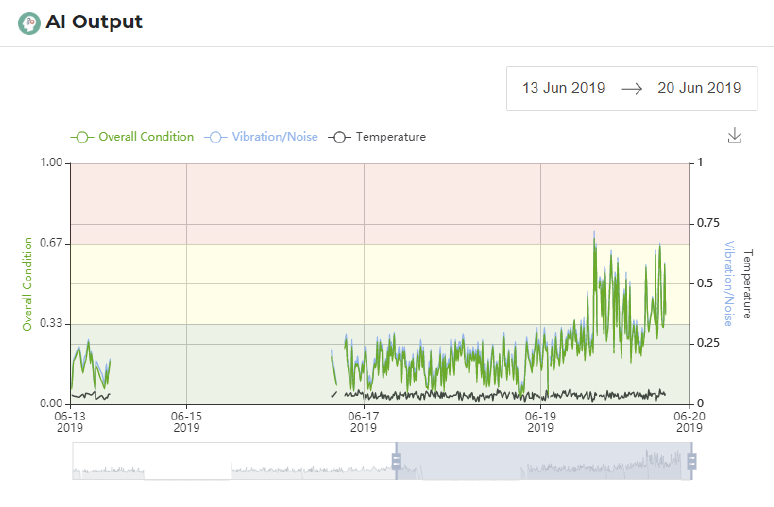

One of the key benefits of continuous condition monitoring is that it acts as an early warning system – giving maintenance teams advance notice of subtle changes that, if left unattended could degrade into more permanent damage or a failure. In late June, one of our chemical and fertiliser manufacturing customers provided feedback to us […]